The spectrum of

vehicle testing activities ranges from type tests of newly constructed or refurbished railway vehicles to research & development tests with the aim of

detecting the reasons and assisting the solution of problems which arose during the operation or maintenance of rail vehicles. The gains from vehicle tests range from the

invaluable life and property protection stemming from the direct prevention of the danger of derailments/accidents to significant cost savings achieved thanks to newly introduced

maintenance/operation instructions based on targeted assessments of the test results.

Type tests serve to confirm the compliance of the features of the vehicle relevant to traffic safety and environmental protection. Static (tension/compression rig) and dynamic (buffing) strength tests serve

to confirm that the vehicle will not suffer permanent deformation in case of the highest expected collective load (as specified in the relevant regulations). Quasi-static derailment

safety tests involve the evaluation of the yaw moment of the bogies, the torsional rigidity of the vehicle body and underframe and the appropriate interaction of the couplers and buffers.

For dynamic (on-track) derailment tests, the vertical and lateral wheel–rail contact forces have to be recorded continuously. The targeted evaluation of these signals is the basis for the targeted assessment of the

vehicle’s safety against derailment, but it is also possible to determine the vertical load of the railway track or the safety against permanent lateral track displacement.

The lateral running stability and ride comfort characteristics of the tested vehicle can also be mapped out in the framework of on-track tests.

The proper functionality of brake systems is a basic requirement of traffic safety. Stopping distance measurements in the form of slip or train-braking tests serve to determine

the indicated braked weight percentage of the vehicle, while wheel slip protection (WSP) tests serve to confirm that the vehicle can stop safely and without any damage

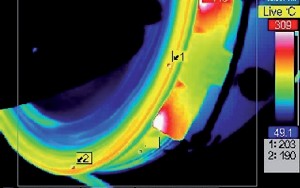

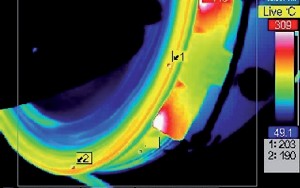

even under dismal ambient conditions. An interesting sub-field of dynamic brake tests is the monitoring of the heat load of the friction parts of the brake system.

In traction and energetics tests, beyond the determination of the resistance to forward movement and the rotational mass factor from tests, one can also derive the characteristic curves and

efficiency factor surfaces of traction vehicles, the power factor and the consumed and regenerated electric energy for electric traction vehicles, and the specific fuel consumption

for diesel vehicles.

External standby, starting and pass-by, as well as internal standby and running noise tests serve to determine the operational noise emission of railway vehicles, the keeping of

which under a stipulated level is an ever more and more accented sub-task of environmental protection.

With the exception of dynamic strength tests, for the above activities, MÁV KFV Kft. JVCs is a testing laboratory accredited by NAH under No. NAH-1-1094/2022 according to EN ISO/IEC 17025.