One of the most important fields of railway track diagnostics is the inspection of the status of the rails. In order to meet

the customers’ high demands as well as to facilitate the modernization of the fleet carrying out the track diagnostic inspections, MÁV KFV Kft. has decided to develop a new

two-section inspection unit, the implementation of which is to be completed in 2016. The diagnostic car has been designed in a way that it carry out inspections on its own in

case of being hauled by a foreign traction unit.

The new diagnostic car has been equipped with state-of-the-art rail diagnostic measuring systems (ultrasonic, eddy-current and rail corrugation), however, the vehicle body

structure was designed to allow installation of further measuring systems without significant modifications. The speed of the inspection train in case the ultrasonic inspection system is active

is 70 km/h on continuous welded rail where the line speed is ≥ 160 km/h and 50 km/h otherwise. The measuring devices can be operated and controlled through a central

system, which supplies all the systems with measuring commands and synchronized location identification data (distance signal + GPS coordinates).

The internal material discontinuities of the rails are uncovered by the ultrasonic detection system, which works with 12 channels and with a special sensor head arrangement, which allows

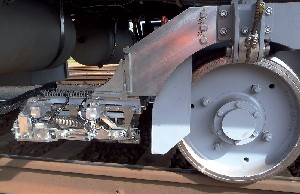

the irradiation of almost the complete cross section of the rails. The accurate positioning of the sensor heads and their safe running over points are ensured by the measuring bogie and

the measuring rod, which is guided between the axles of the bogie. The assessment based on the ultrasonic B-figure is supported by a high-quality video recording which shows both the

the track–centre-facing side as well as the running surface of the rails.

The inspection train detects defects resulting from rolling contact fatigue (RCF) with eddy-current technology. The measuring system is equipped with four probes per rail to inspect

the strips of the running and guiding surfaces most exposed to rail head cracking. The inspection mechanism is installed on the measuring bogie. The measuring system provides figures

of the maximum damage depth of the surface cracking per meter as well as the number of cracks.

The system measures the rail corrugation with inductive probes on a basis-length of 230 mm. The characteristic wave-length is calculated by a mathematical model based on the measuring results.